Mono Evolver Keyboard: DeoxIT

Treating your encoders is a relatively simple procedure involving nothing more than a screwdriver and some Deoxit.

Tools needed: Phillips head screwdriver.

Treating the Encoders:

If the encoders become oxidized, they can skip values or behave erratically. The best way to treat the encoders is to remove the panel boards and apply a product called Deoxit directly to the encoder housing. Some customers have reported successfully treating the encoders by applying Deoxit to the encoder shafts without removing the boards, but we don’t recommend it.

We use both the 5% and 100% solutions of Deoxit. If you are only using one, we recommend the 100%. It is easiest to apply using the needle dispenser bottles. The tubes also work well. The sprays are not particularly well suited to this application.

Getting inside the Mono Evolver Keyboard:

To start, unplug all power/audio/MIDI cables.

1. There are two panel boards in the Mono Evolver Keyboard. For removing both panel boards, first take the knobs off by pulling straight up. They are not attached and just slide on and off, no twisting required. Proceed to step #2.

For removing individual panel boards: the dividing line is between the Low Pass Filter velocity and Low Pass Filter key amount parameters.

- For the left panel board only, start at the Low Pass Filter velocity parameter. Remove this knob, any knob inline with it, and all knobs to the left of it.

- For the right panel board only, start at the Low Pass Filter key amount parameter. Remove this knob, any knob in line with it, and all knobs to the right of it.

2. Unscrew the 4 screws on the front panel.

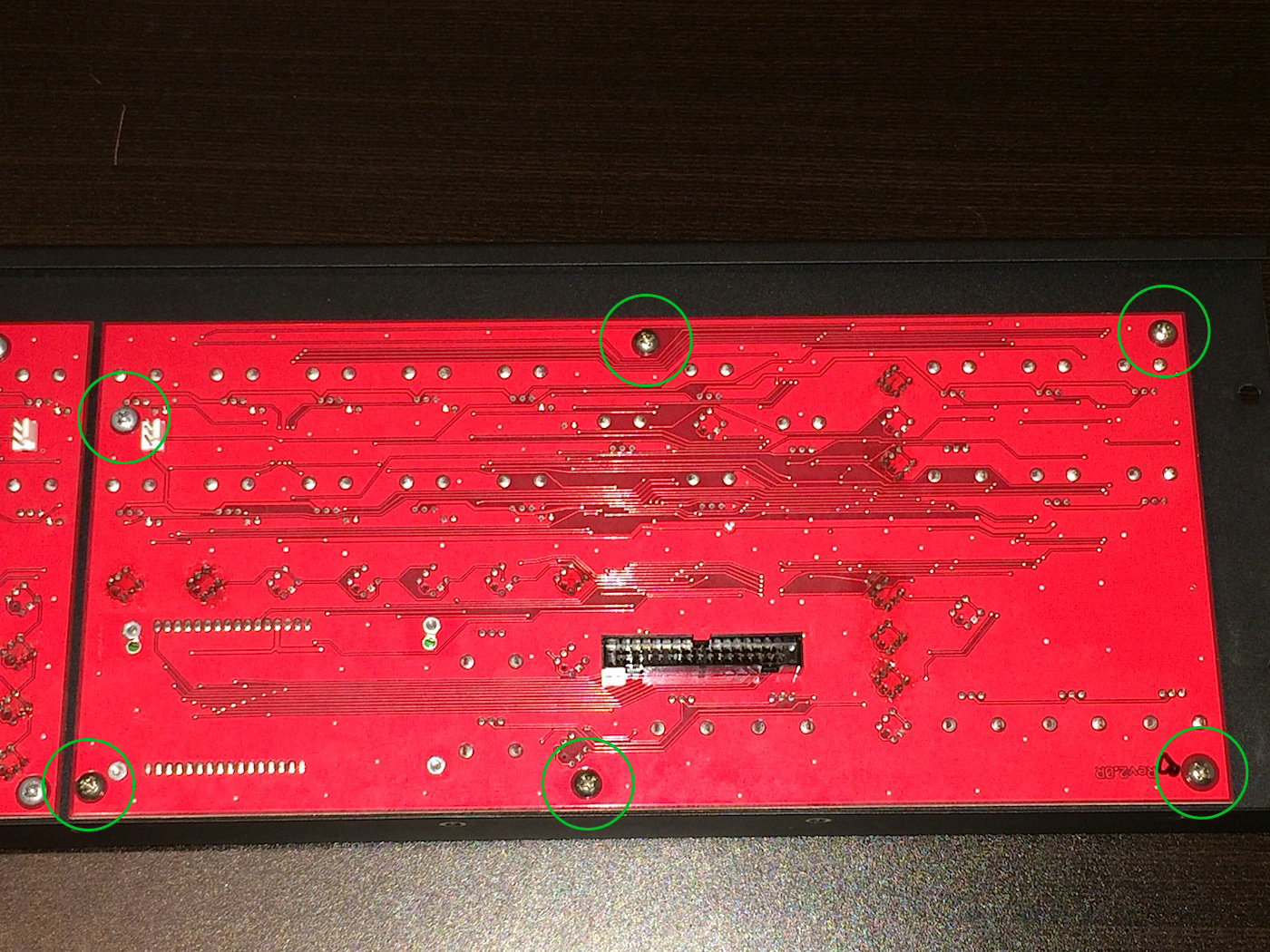

3. Now unscrew the 7 screws along the back panel.

4. Place a piece of soft material behind the Mono Evolver (bubble wrap, towel, blanket, etc..)

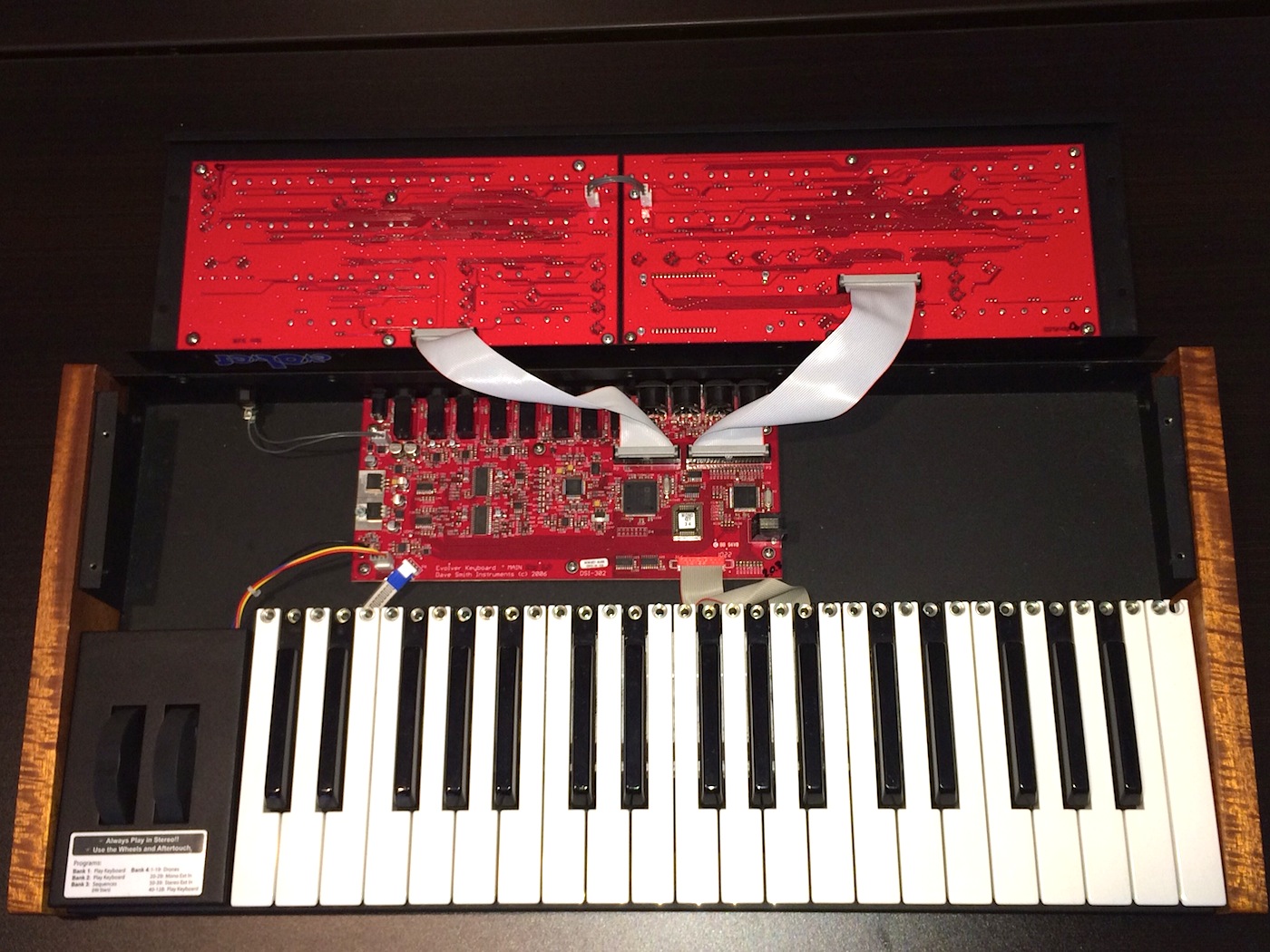

5. Lift the front panel up and off the Mono Evolver, set it face down on the soft material. Your panel boards and main board could be green or red.

Removing the panel boards:

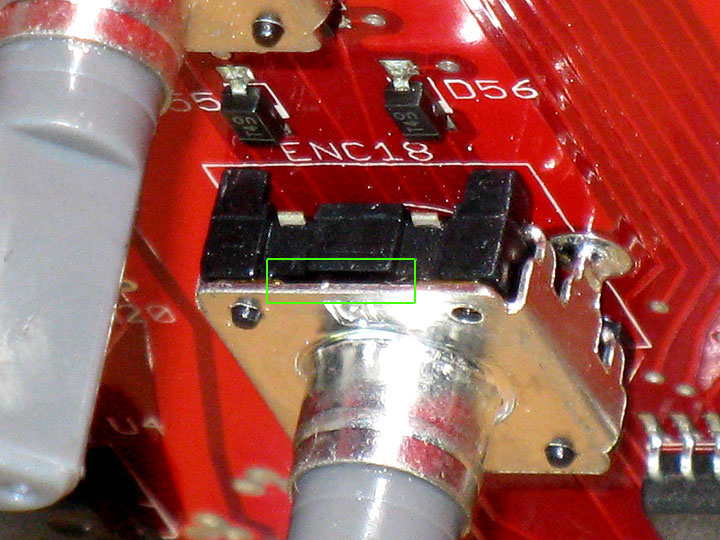

1. You will see 2 ribbon cables running from the main PCB board to the 2 front panel boards. If you have a Potentiometer Edition (PE), there will also be a small 3-pin jumper cable connecting the left and right panel boards. Note the orientation of the ribbon cables as they must be re-installed in the same manner.

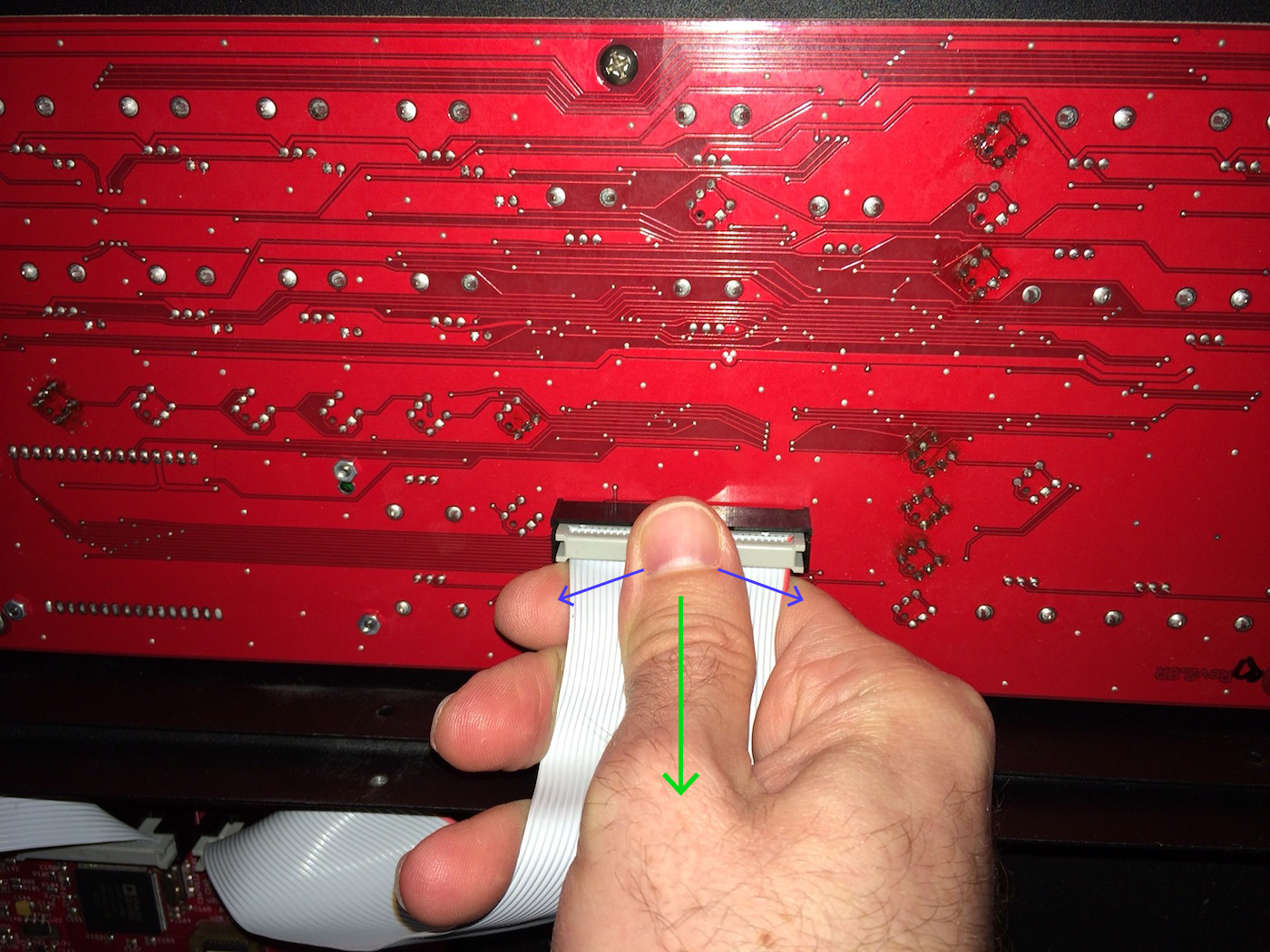

2. Remove the ribbon cables from the front panel boards. Place your index finger beneath the ribbon cable’s connector next to its receptacle. Place your thumb on top of the ribbon’s connector and remove it from its receptacle by rocking back and forth with medium force. DO NOT PULL the ribbon cable itself.

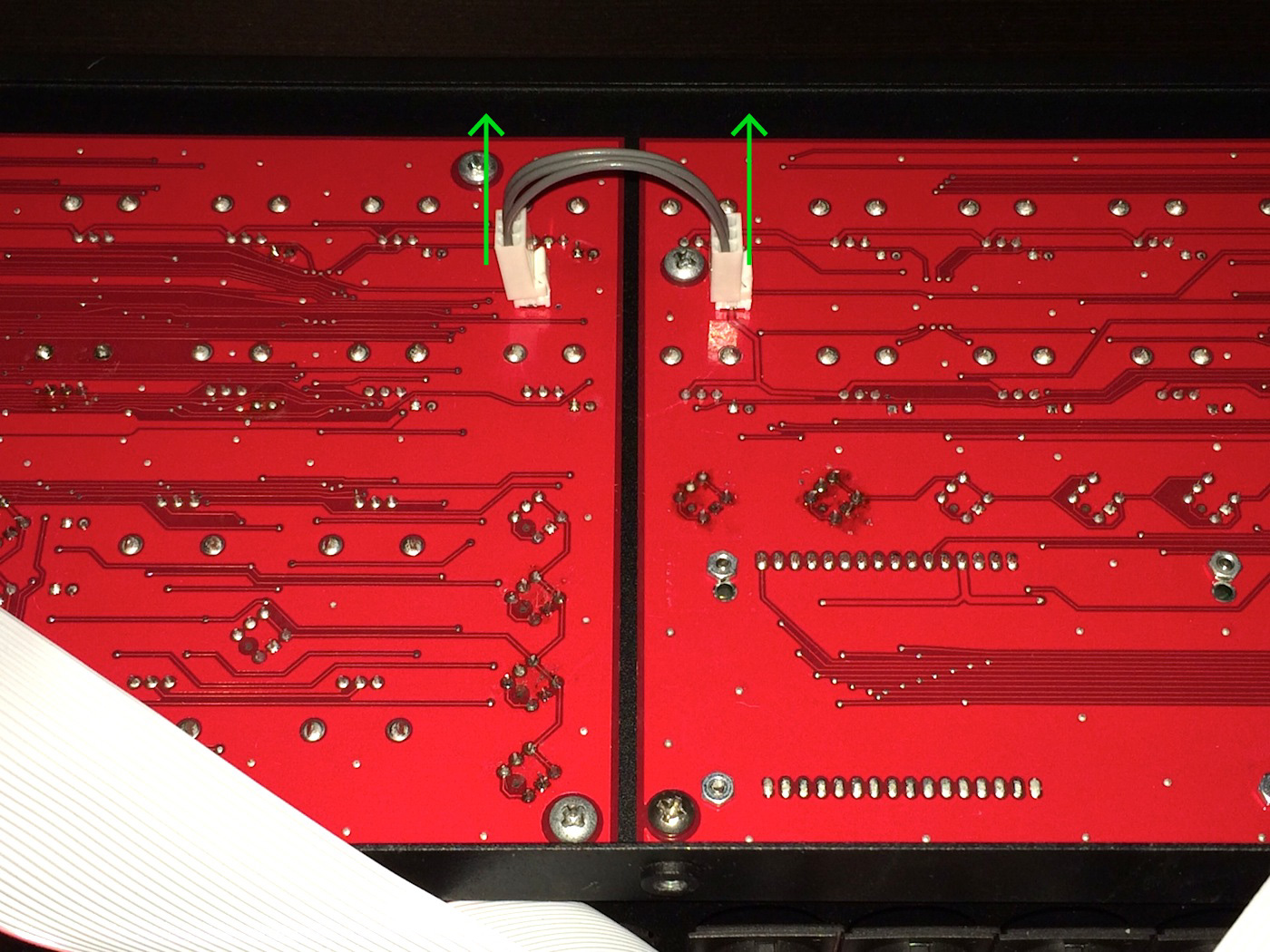

3. If you have a Potentiometer Edition (PE), remove the 3-pin jumper cable running between the panel boards by pulling straight up on the connector only with a slight wiggle. Do this one side at a time. DO NOT pull on the wires.

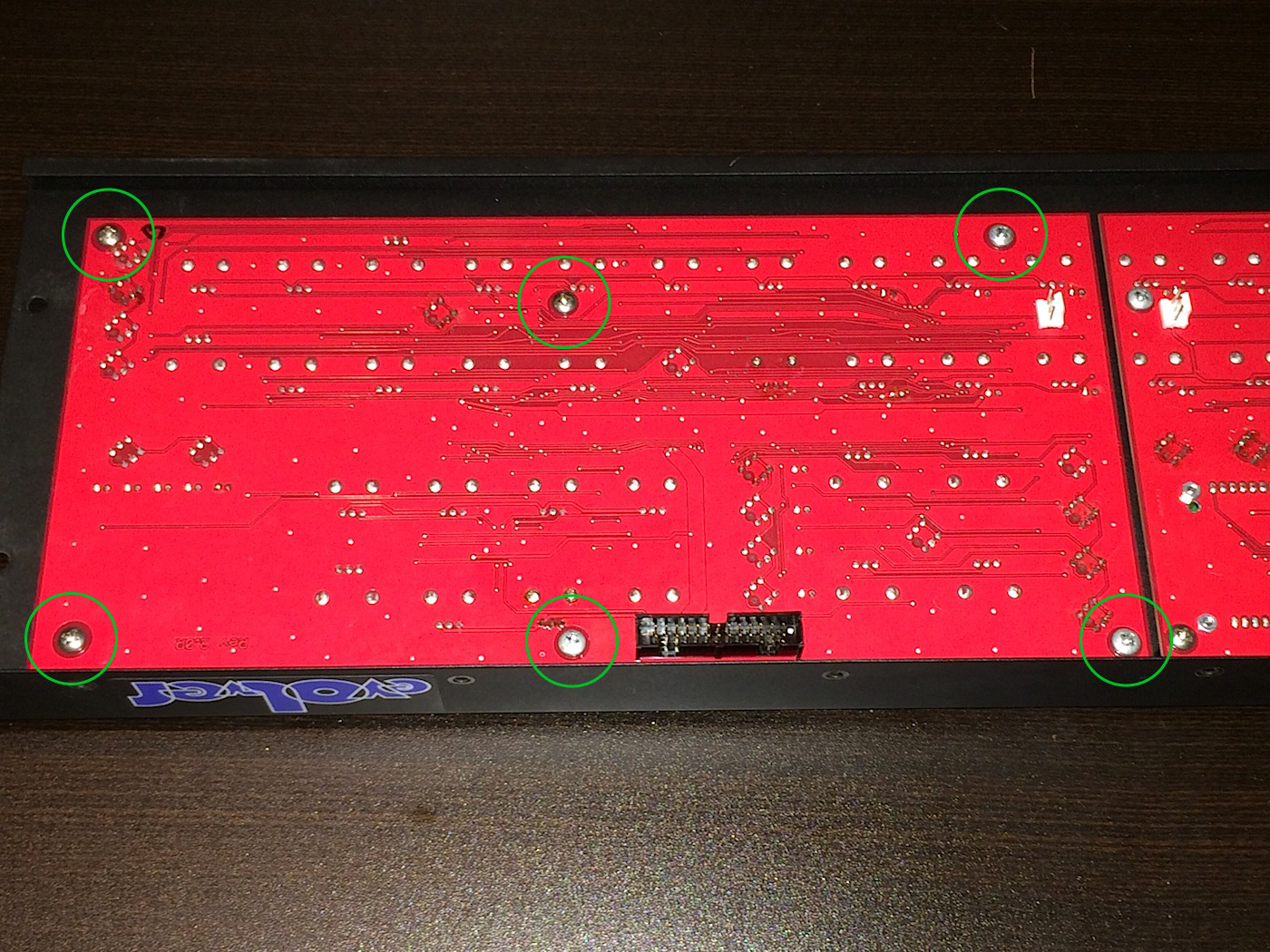

4. Unscrew the 6 screws holding each panel board to the front panel.

The panel boards can now be removed.

Applying the Deoxit

The encoders have three leads. On the side opposite the leads, there is a narrow crack between the encoder’s metal top and the plastic housing. That is where you will apply the Deoxit.

1. Lean the board against something so that it is nearly vertical, with the encoder leads facing down.

2. If you are using both the 5% and 100% solutions, start with the 5%. (The 5% is thinner and, therefore, application is a little easier. And it makes the 100% go in easier, as well.) Apply a drop of Deoxit directly to the crack on an encoder. The first drop takes a little longer to work its way in, but it gets easier with successive drops.

3. Turn the encoder shaft between drops to distribute the Deoxit inside the encoder. Apply two or three drops of the 5% and then two drops of the 100%. If you are using just the 100%, apply three drops.

4. Wipe off any excess.

5. After treating the encoders, lay the board flat and give the encoders a turn.

One treatment is typically enough to get the encoders working like new, but particularly stubborn encoders sometimes require a second application. Also, it may help to let the boards sit overnight before use. Also note, treating your encoders with Deoxit will often result in a “looser” feel when turning them.

Please contact DSI Technical Support if you have any questions regarding this procedure.